Acrylic Cnc Service

Acrylic CNC service has become an essential component in the manufacturing industry, particularly in the production of customized parts and products. The versatility of acrylic materials, combined with the precision of Computer Numerical Control (CNC) technology, enables the creation of complex designs and shapes with high accuracy. As a result, acrylic CNC services are in high demand across various sectors, including architecture, engineering, and product design. In this article, we will delve into the world of acrylic CNC services, exploring the benefits, applications, and technical aspects of this innovative technology.

Introduction to Acrylic CNC Service

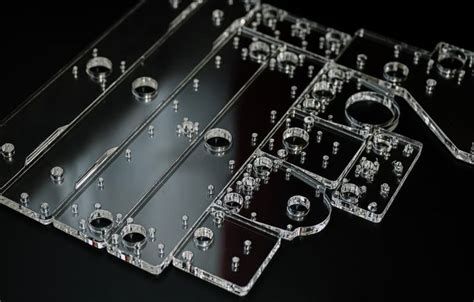

Acrylic, also known as polyacrylate or polymethyl methacrylate (PMMA), is a transparent and rigid plastic material widely used in various industries. Its excellent optical clarity, impact resistance, and ease of fabrication make it an ideal choice for applications such as signage, displays, and architectural features. CNC technology, on the other hand, allows for precise control over machining processes, enabling the production of complex shapes and designs with high accuracy. The combination of acrylic materials and CNC technology gives rise to a powerful manufacturing solution, capable of producing customized parts and products with exceptional quality and precision.

Key Points

- Acrylic CNC service offers high-precision machining of acrylic materials

- CNC technology enables the production of complex designs and shapes

- Acrylic materials exhibit excellent optical clarity, impact resistance, and ease of fabrication

- Applications of acrylic CNC services include signage, displays, architectural features, and product design

- Benefits of acrylic CNC services include fast turnaround times, high accuracy, and cost-effectiveness

Benefits of Acrylic CNC Service

The integration of acrylic materials and CNC technology offers numerous benefits, including fast turnaround times, high accuracy, and cost-effectiveness. With acrylic CNC services, manufacturers can produce customized parts and products quickly and efficiently, reducing lead times and improving overall productivity. Additionally, the high precision of CNC technology ensures that the final products meet exacting specifications, minimizing errors and reducing waste. The cost-effectiveness of acrylic CNC services is also a significant advantage, as it allows manufacturers to produce complex designs and shapes without incurring excessive costs.

| Material | Thickness | CNC Machining Capability |

|---|---|---|

| Acrylic | 1/8" - 1" | Cutting, drilling, milling, and engraving |

| Polycarbonate | 1/8" - 1/2" | Cutting, drilling, and milling |

| ABS | 1/8" - 1/2" | Cutting, drilling, and milling |

Applications of Acrylic CNC Service

Acrylic CNC services have a wide range of applications across various industries, including architecture, engineering, and product design. In the field of architecture, acrylic CNC services are used to create complex designs and shapes for building features, such as decorative panels, signage, and displays. In engineering, acrylic CNC services are used to produce customized parts and components, such as prototypes, models, and functional parts. In product design, acrylic CNC services are used to create innovative and functional products, such as consumer electronics, medical devices, and automotive components.

Technical Aspects of Acrylic CNC Service

The technical aspects of acrylic CNC services involve the use of specialized software and equipment to design and manufacture customized parts and products. The process typically begins with the design phase, where computer-aided design (CAD) software is used to create a digital model of the part or product. The CAD file is then imported into computer-aided manufacturing (CAM) software, which generates the machining code and controls the CNC machine. The CNC machine uses a variety of tools, such as cutting tools, drilling tools, and milling tools, to machine the acrylic material and produce the final product.

What is the typical turnaround time for acrylic CNC services?

+The typical turnaround time for acrylic CNC services can range from a few days to several weeks, depending on the complexity of the design and the quantity of parts being produced.

What is the maximum thickness of acrylic material that can be machined using CNC technology?

+The maximum thickness of acrylic material that can be machined using CNC technology can range from 1" to 2", depending on the type of CNC machine and the cutting tools being used.

Can acrylic CNC services be used to produce complex designs and shapes with high accuracy?

+Yes, acrylic CNC services can be used to produce complex designs and shapes with high accuracy, thanks to the precision of CNC technology and the versatility of acrylic materials.

In conclusion, acrylic CNC services have become an essential component in the manufacturing industry, offering a powerful solution for producing customized parts and products with high accuracy and precision. With its versatility, cost-effectiveness, and fast turnaround times, acrylic CNC services have a wide range of applications across various industries, including architecture, engineering, and product design. As the demand for customized parts and products continues to grow, the importance of acrylic CNC services will only continue to increase, driving innovation and advancement in the manufacturing industry.